| Dia. | Colour | Sales/Unit | Unit/Carton | Reference |

|---|---|---|---|---|

| 6 mm | White | 100 m | 8 /A | W4506WI |

| 6 mm | Black | 100 m | 8 /A | W4506NO |

| 6 mm | Grey | 100 m | 8 /A | W4506GI |

| 6 mm | Blue | 100 m | 8 /A | W4506BL |

| 6 mm | Green | 100 m | 8 /A | W4506VE |

| 6 mm | Red | 100 m | 8 /A | W4506RE |

| 8 mm | White | 100 m | 4 /A | W4508WI |

| 8 mm | Black | 100 m | 4 /A | W4508NO |

| 8 mm | Grey | 100 m | 4 /A | W4508GI |

| 8 mm | Blue | 100 m | 4 /A | W4508BL |

| 8 mm | Green | 100 m | 4 /A | W4508VE |

| 8 mm | Red | 100 m | 4 /A | W4508RE |

| 10 mm | White | 100 m | 2 /B | W4510WI |

| 10 mm | Black | 100 m | 2 /B | W4510NO |

| 10 mm | Grey | 100 m | 2 /B | W4510GI |

| 10 mm | Blue | 100 m | 2 /B | W4510BL |

| 10 mm | Green | 100 m | 2 /B | W4510VE |

High abrasion resistant shock cord

Monoflex polyethylene (PE)

Applications

General industry: Lifting - Lashing - Protective tarpaulins and nets / safety for scaffolding - Protective nets for storage - Winter covers for pools

Transport: Tarpaulins for trucks and trailers - Skip nets on dumptrucks

Advertising/Events: Tarpaulins and banners - Flags - Billboards - Marquees and tents

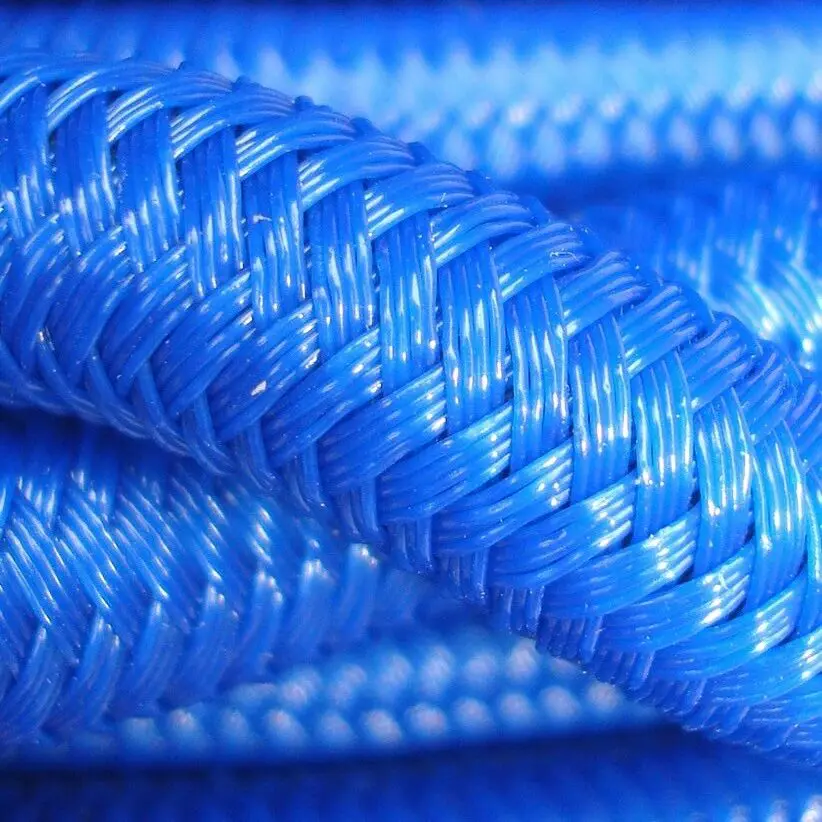

This high abrasion and U.V. resistant shock cord was designed with a single Monoflex core, simplifying its use when fitted through tarp eyelets or assembling fittings.

The 650 denier PE covering and the monofilament with anti U.V. agents in its core makes this shock cord a great choice for outside work.

The outer covering of W45 is made of PE with 650 denier which provides the best protection against abrasion in our whole product range, insuring long life under tough conditions. This makes it a great product for industry.

This shock cord offers standard comfort and flexibility. The W45 has the unique feature to be made of a single solid rubber core which offers a cleaner cut than a multi thread shock cord. When cut, the single-thread rubber core keeps a nice round shape which simplifies the work when fittings are added or when the shock cord is passed through eyelets. The PE outer covering has a tough touch that is hard to bend and to make knots.

Monoflex PE bungee cord has a high pulling force; this implies that the cord has a high resistance to stretch. The strong return force suits industrial uses such as safety nets, storage nets, lifting and lashing.

The strength at break of W45 is amongst the high ones in our product range, meaning it will resist a high pulling force before breaking, insuring security for workers and goods.

| Nominal diameter in mm | 6 | 8 | 9 | 10 |

| Yarn type | Polyethylene | |||

| Number of threads in the yarn | 48 | 64 | 64 | 64 |

| Colors | Black - White - Green - Blue - Grey - Red | |||

| Net weight per 100 m in Kg | 2.1 | 4.22 | 6.1 | 7.54 |

| Strength in N at 25% stretch | 21 | 31 | 53 | 64 |

| Strength in N at 50% stretch | 31 | 41 | 71 | 88 |

| Strength in N at 75% stretch | 44 | 51 | 92 | 110 |

| Strength in N at 100% stretch | 76 | 64 | 128 | 147 |

| Elongation at break in % | 190 | 230 | 200 | 200 |

| Strength at break in Newton | 618 | 961 | 1049 | 1098 |

| Tolerance on stretch and break | +/- 15 % | |||

| Range of use | 25 to 75 % elongation | |||

Outer covering: Polyethylene 650 denier monofilament yarn CAS No. 9002-88-4. Incompatible materials: Strong oxidizing agents. Nonhazardous to environment under normal usage.

UV. resistant tests: Polyethylene yarn stable under UVB-313 / 144h, exposure conditions 8h cycles @ 60 ° / 4h @ 50.

Wear and abrasion: Tested ISO 12947-2 Over 4000 cycles before first signs of damage.

Inner core: Mono thread of natural extruded rubber with anti UV agents