| 10 and 20 meters lengths | ||||

|---|---|---|---|---|

| Dia. | Colour | Sales/Unit | Unit/Carton | Reference |

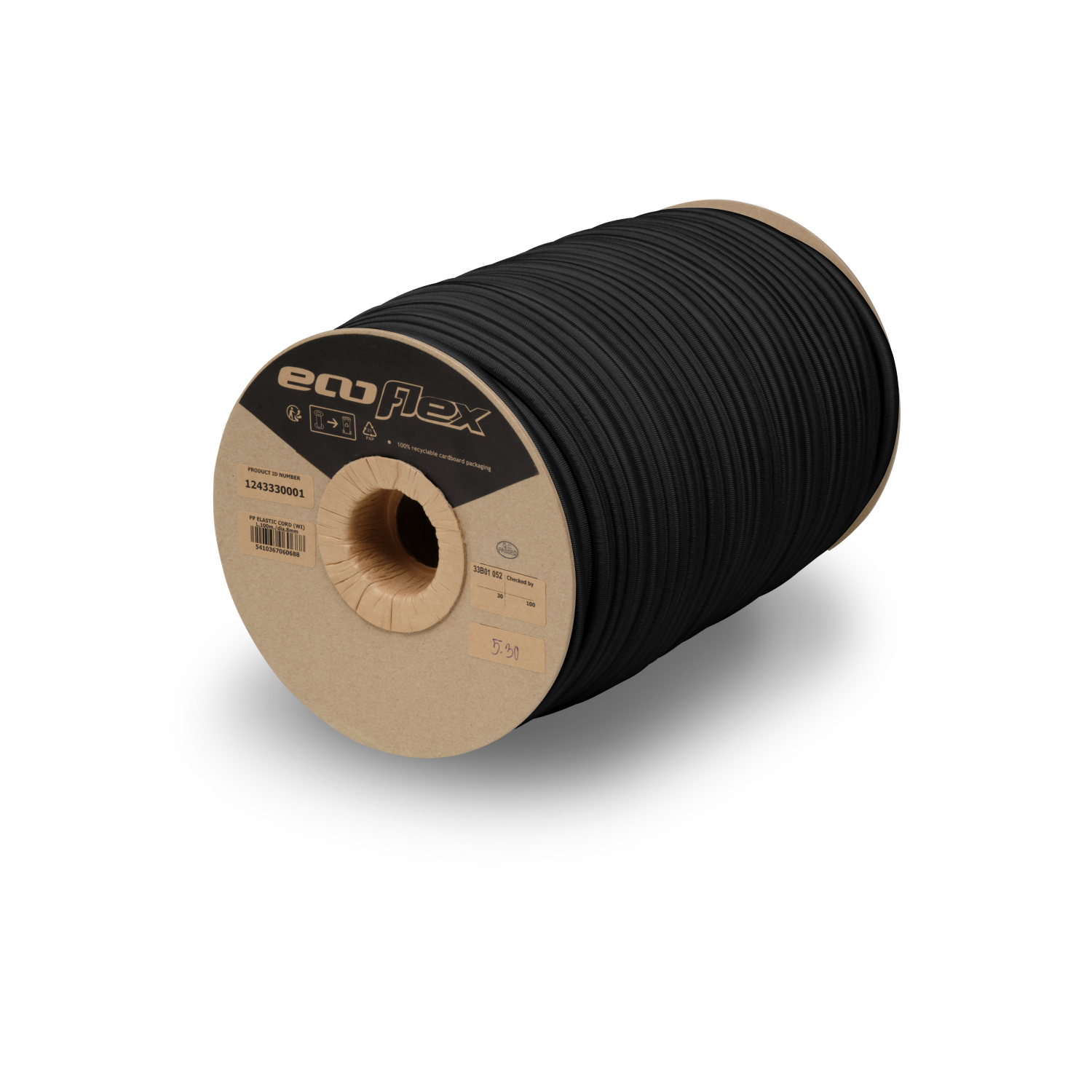

| 6 mm | Black | 10 m | 80 /A | W5606NO/10 |

| 6 mm | Black | 20 m | 40 /A | W5606NO/20 |

| 8 mm | Black | 10 m | 40 /A | W5608NO/10 |

| 8 mm | Black | 20 m | 20 /A | W5608NO/20 |

| 8 mm | Blue | 20 m | 20 /A | W5608BL/20 |

| 8 mm | Grey | 20 m | 20 /A | W5608GI/20 |

| 10 mm | Black | 10 m | 24 /A | W5610NO/10 |

| 10 mm | Black | 20 m | 12 /A | W5610NO/20 |

| 100 meters reels | ||||

|---|---|---|---|---|

| Dia. | Colour | Sales/Unit | Unit/Carton | Reference |

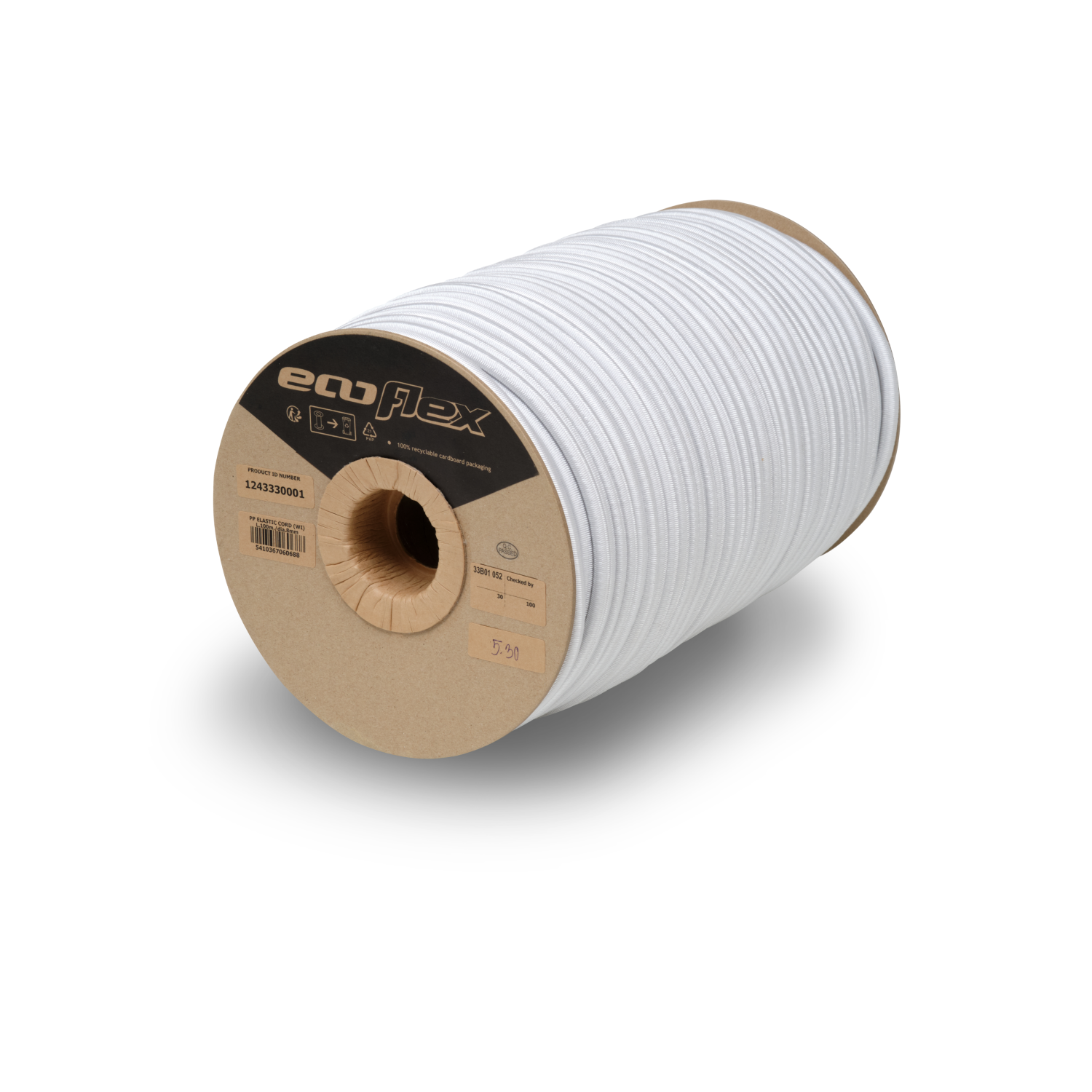

| 6 mm | White | 100 m | 8 /A | W5606WI |

| 6 mm | Black | 100 m | 8 /A | W5606NO |

| 6 mm | Black | 50 m | 12 / A | W5606NO/50 |

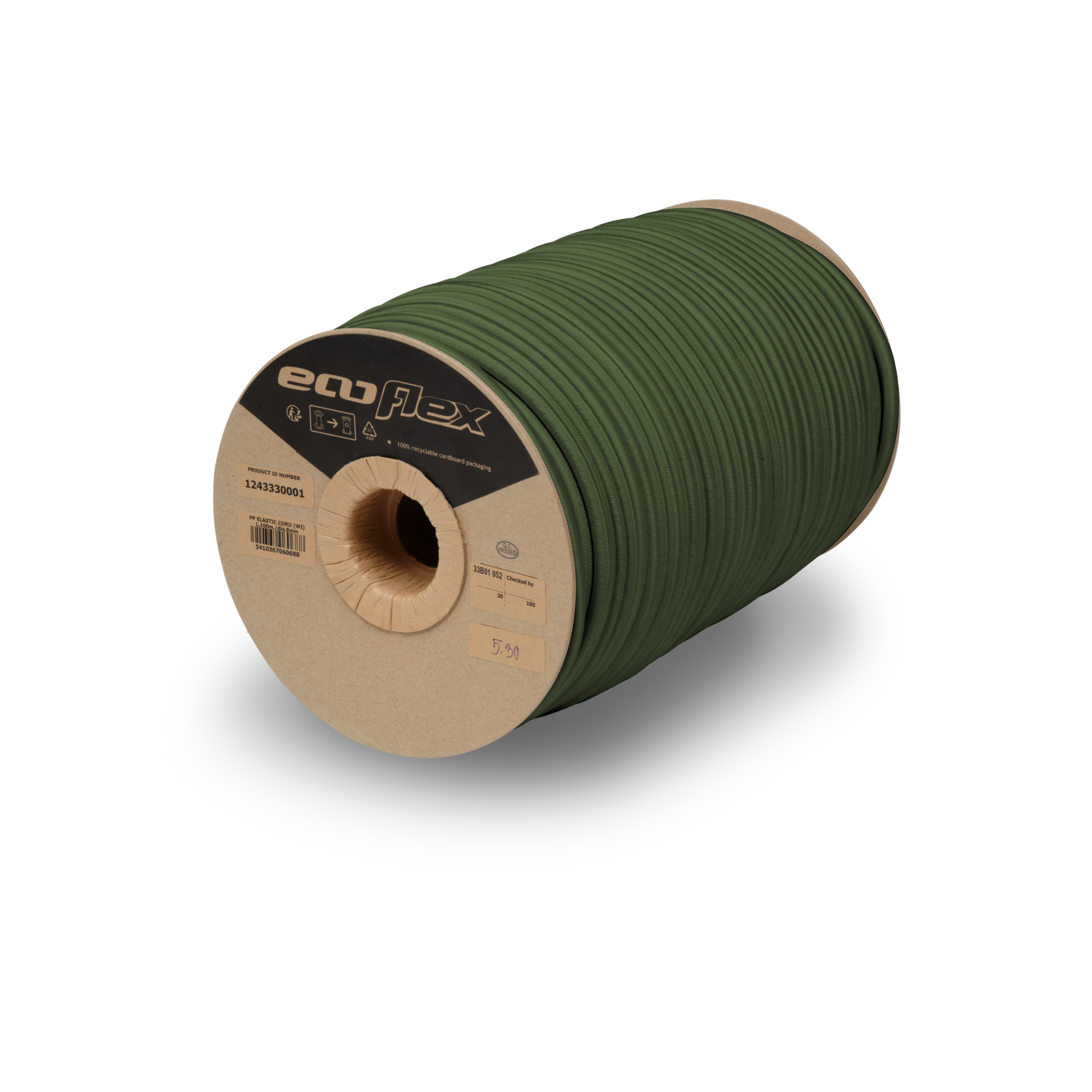

| 6 mm | Nato green | 100 m | 8 /A | W5606OG |

| 8 mm | White | 100 m | 4 /A | W5608WI |

| 8 mm | Black | 100 m | 4 /A | W5608NO |

| 8 mm | Nato green | 100 m | 4 /A | W5608OG |

| 10 mm | White | 100 m | 2 /B | W5610WI |

| 10 mm | Black | 100 m | 2 /B | W5610NO |

| 10 mm | Nato green | 100 m | 2 /B | W5610OG |